Medical Industry

Welcome to VPI Innovative Industries

Medical Summary

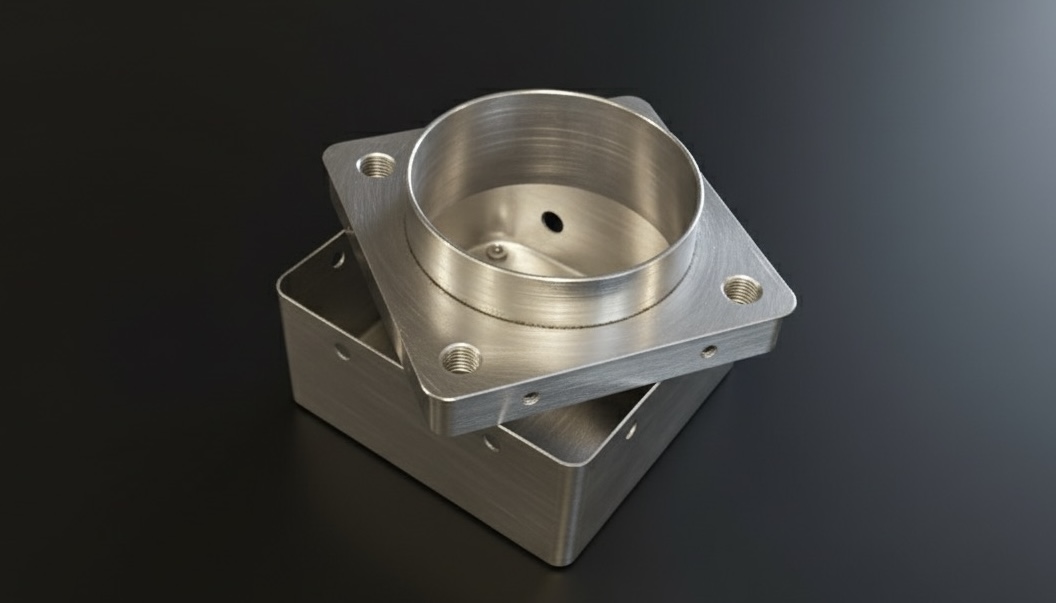

At VPI Innovative Solutions, we manufacture precision components used in medical equipment and critical healthcare devices, where accuracy, reliability, and cleanliness are essential. Our machining processes and inspection controls ensure every part meets stringent biocompatibility and dimensional standards required in the medical domain.

Technical Capabilities

Our infrastructure includes multi-axis CNC machining, turn-mill centers, and sliding head technology, enabling the manufacture of intricate geometries and close-tolerance fits.

Every process is validated through statistical process control (SPC) and verified using Mitutoyo CMM systems, contour measurement, and surface roughness analysis to maintain full traceability and compliance with customer requirements.

Materials We Machine

We specialize in medical-grade and biocompatible materials, optimized for strength, corrosion resistance, and sterilization stability:

- Stainless Steels: SS304, SS316L, SS410, SS420

- Aluminium Alloys: AL6061, AL7075

- Titanium Alloys: Ti-6Al-4V and medical-grade variants

- Brass and Copper Alloys for electrical and fluidic interfaces

- Engineering Plastics: PEEK, Delrin, PTFE, UHMWPE

Each material is machined using controlled parameters to ensure micro-finish quality, dimensional stability, and repeatable performance.

Post-Machining & Finishing

We offer specialized post-machining and finishing operations suited for medical applications:

- Surface Treatments: Passivation, Electropolishing, Anodizing, Ultrasonic Cleaning

- Heat Treatments: Stress relieving, solution annealing, age hardening

- Micro-deburring, Super-finishing, and Controlled Surface Preparation

All processes are carried out in a controlled environment, ensuring contamination-free surfaces, superior corrosion resistance, and optimal biocompatibility.

Our Focus

Through advanced process engineering, precision machining, and rigorous quality validation, VPI Innovative Solutions supports the medical sector with components that deliver functional accuracy, mechanical integrity, and long-term reliability in every critical assembly.