ENERGY

Welcome to VPI Innovative Industries

Energy Summary

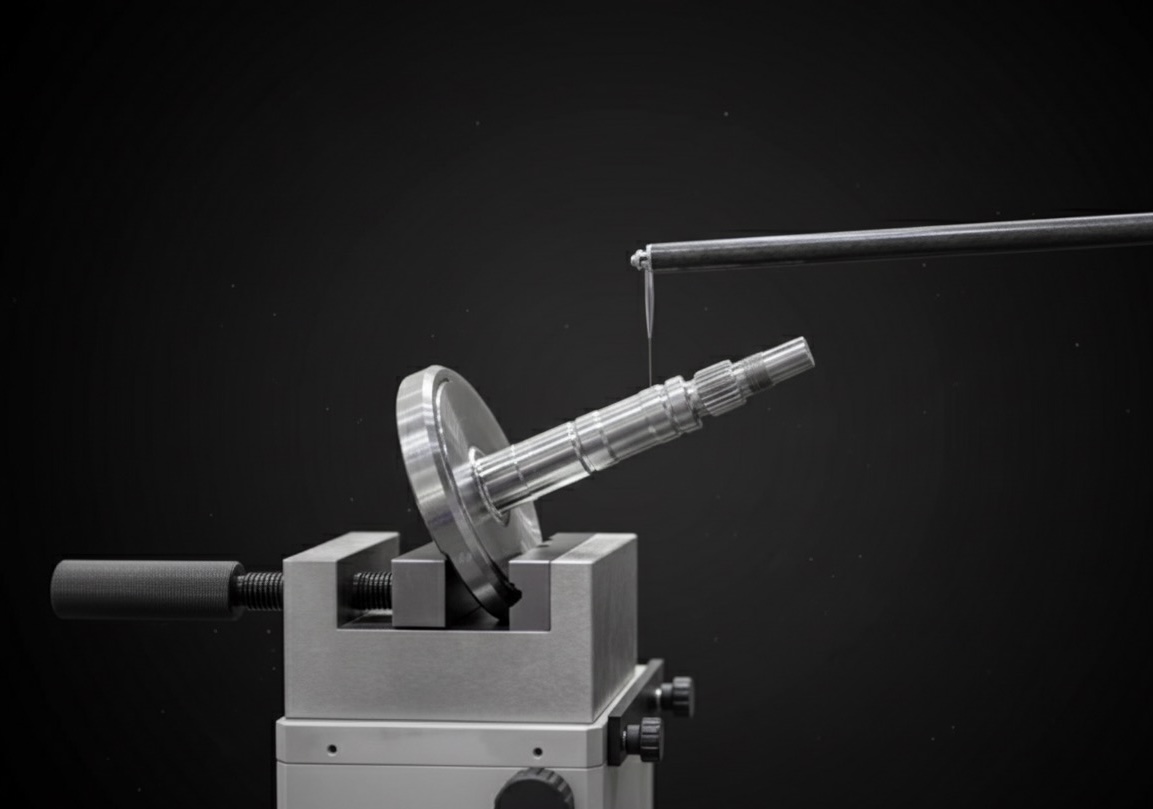

At VPI Innovative Solutions, we manufacture precision components that meet the stringent performance and dimensional standards of the energy sector, where reliability and surface integrity directly impact efficiency and longevity. Our processes are engineered to deliver tight tolerances up to ±10 microns with exceptional surface finish and repeatable accuracy across complex geometries.

Technical Capabilities

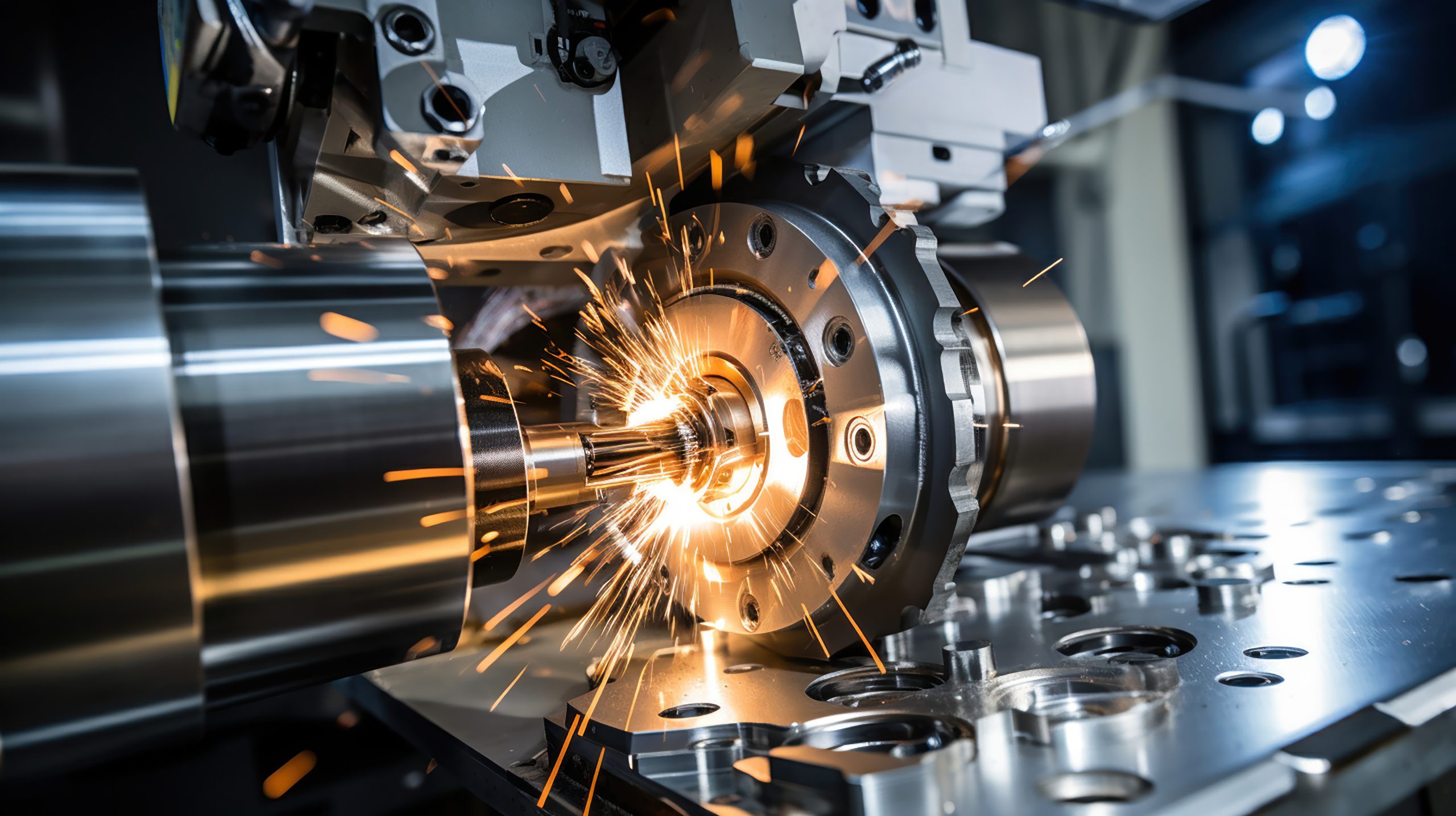

Our advanced machining infrastructure includes multi-axis CNC machining, turn-mill centers, and 5-axis Wire EDM systems, enabling us to produce intricate profiles, sharp internal corners, and fine details with high dimensional stability.

Wire EDM technology allows for burr-free edges and sub-micron precision on critical features, essential for sealing, flow control, and high-load components.

Quality and Process Control

All operations are executed under strict process control and environmental stability, ensuring uniformity in mechanical and surface properties.

Comprehensive verification through CMM inspection, surface roughness testing, and form measurement ensures each part adheres to exact customer specifications and functional requirements.

Surface Finish & Post-Processing

We specialize in achieving superior micro-finish quality, ensuring minimal friction, improved fatigue life, and enhanced performance under high-stress conditions.

Complementary post-machining processes include grinding, lapping, polishing, and controlled heat treatments, ensuring every component performs with maximum efficiency and consistency in service.

Our Focus

With deep precision engineering expertise and robust inspection systems, VPI Innovative Solutions supports the energy sector through components that meet tight tolerance requirements, demanding surface finish standards, and complex geometrical challenges — delivering performance where precision defines reliability.