DIE & MOLD

Welcome to VPI Innovative Industries

Die&Mold Summary

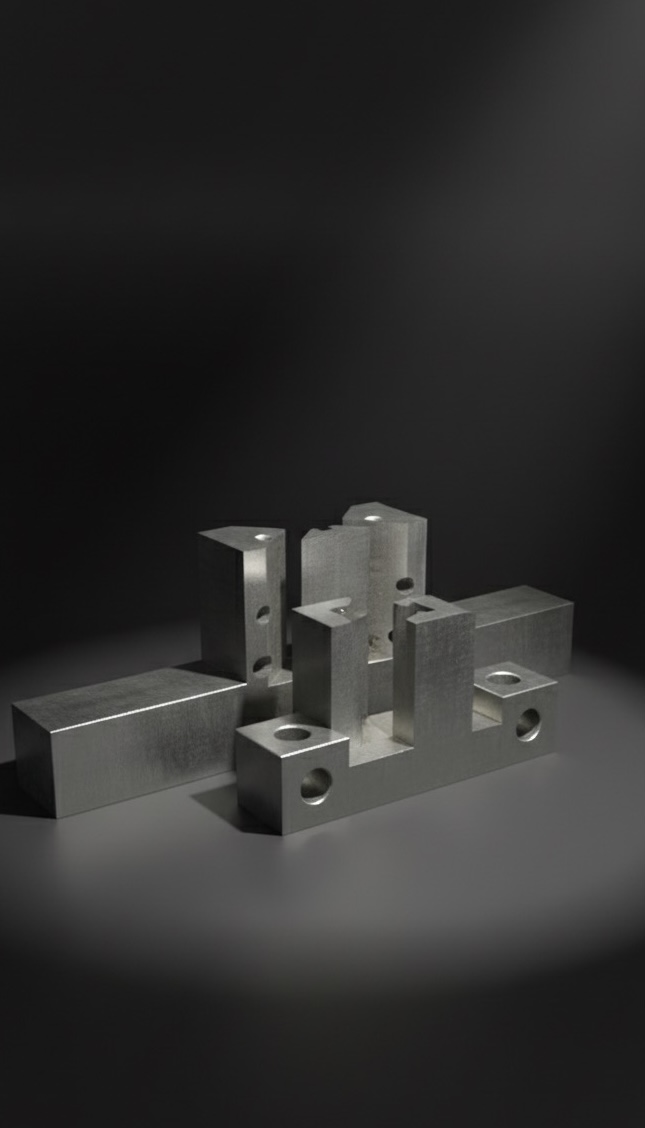

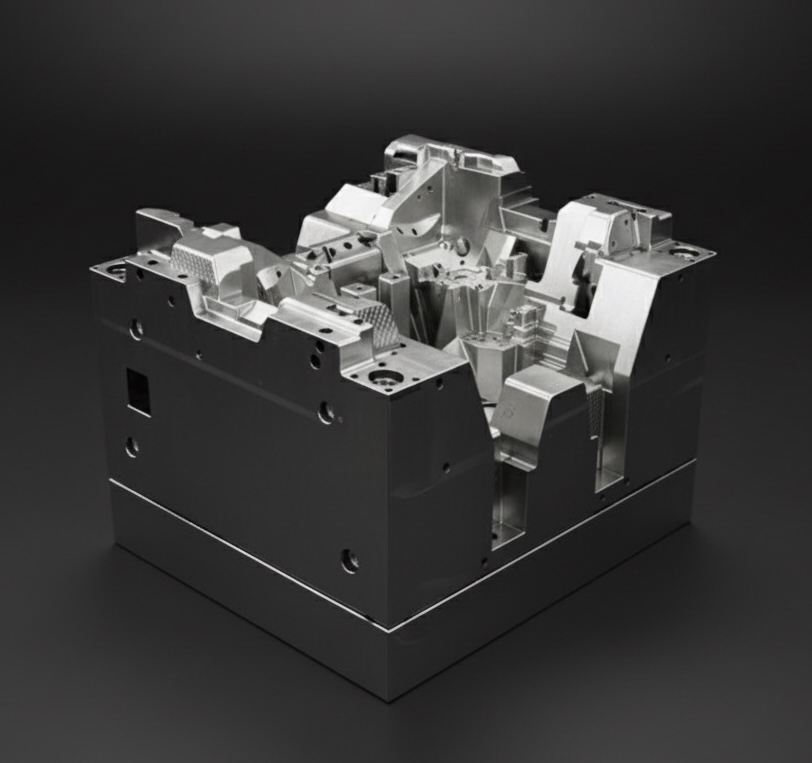

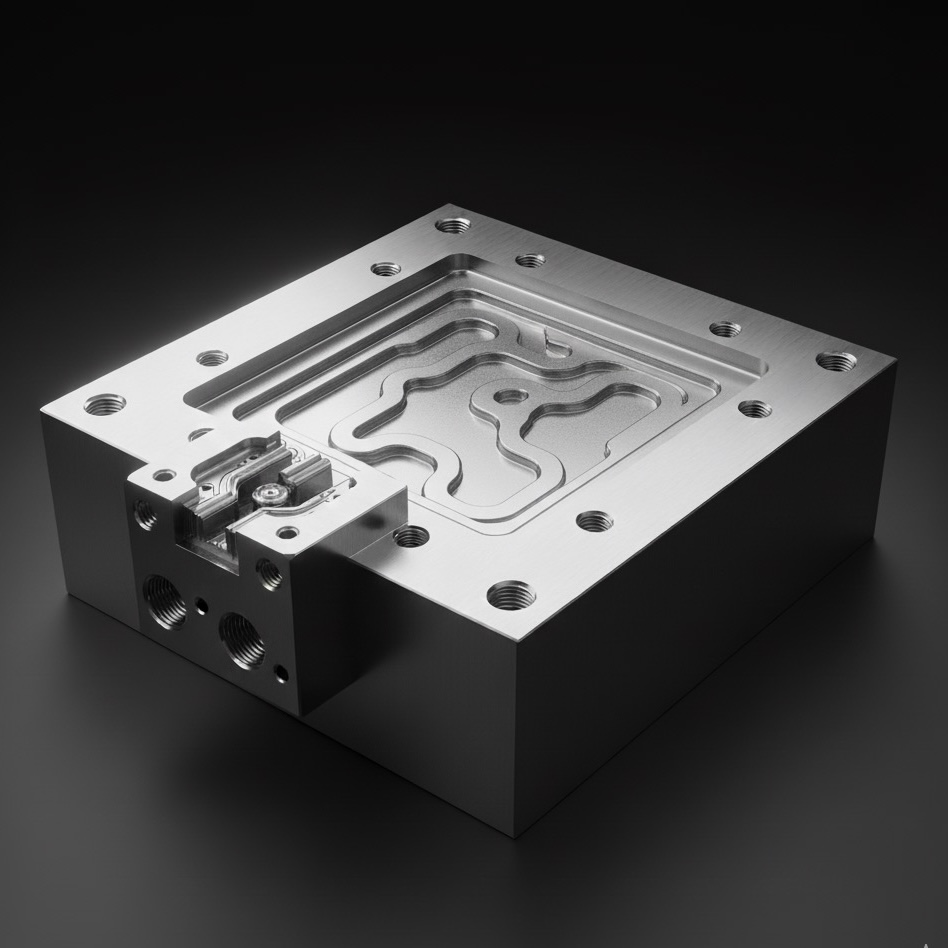

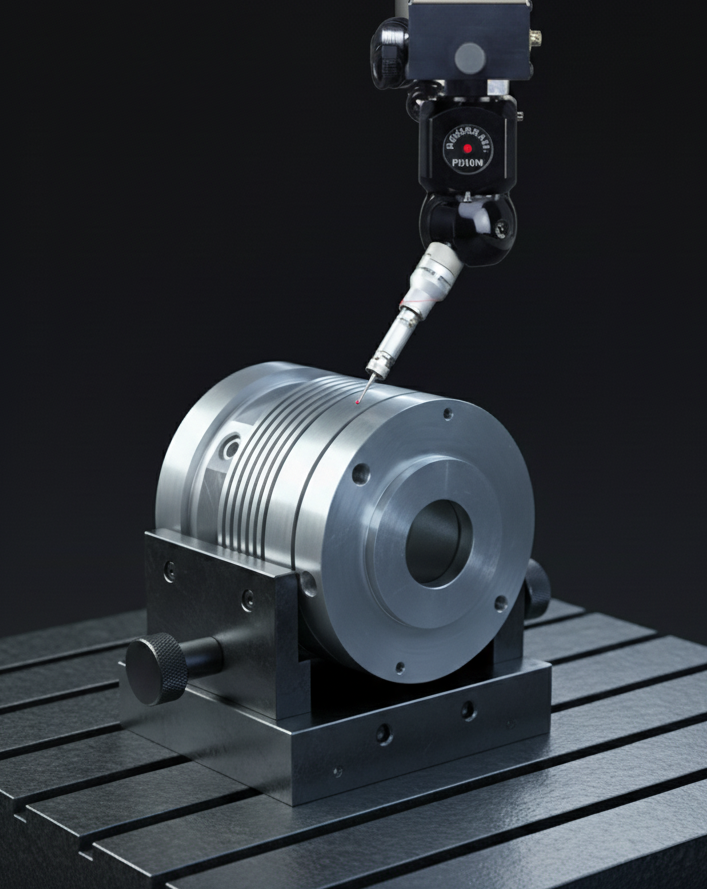

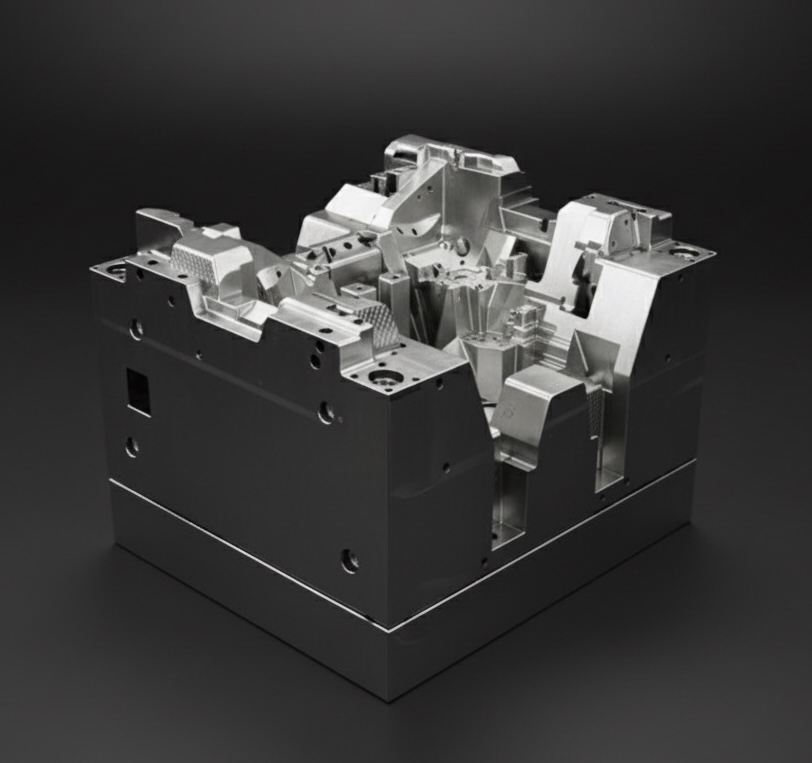

At VPI Innovative Solutions, we deliver advanced machining solutions for the Die & Mould industry, where accuracy, surface finish, and dimensional stability are critical to performance and tool life.

Technical Capabilities

Our facility is equipped with state-of-the-art multi-axis machining centers, including high-speed vertical milling and 5-axis simultaneous milling systems capable of handling components up to 900 mm in size. With spindle speeds up to 20,000 RPM, through-spindle coolant systems, and high-rigidity fixturing setups, we achieve exceptional contour accuracy, surface integrity, and repeatable dimensional control across complex geometries.

We work extensively with tool steels (D2, H13, P20, EN31, A2, and special pre-hardened grades), hardened stainless steels, and special alloy materials used in high-performance mould and die tooling. Our machining process is fully optimized through CAM-based toolpath simulation (Mastercam/HyperMill), ensuring efficient tool engagement, minimal thermal distortion, and precise corner definition on intricate cavities and inserts.