Robotics Industry

Welcome to VPI Innovative Industries

Robotics Summary

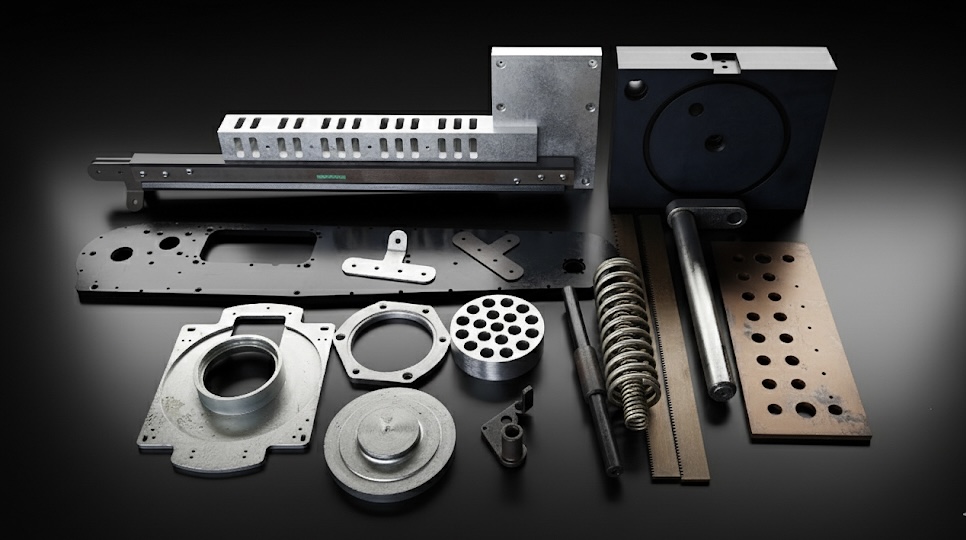

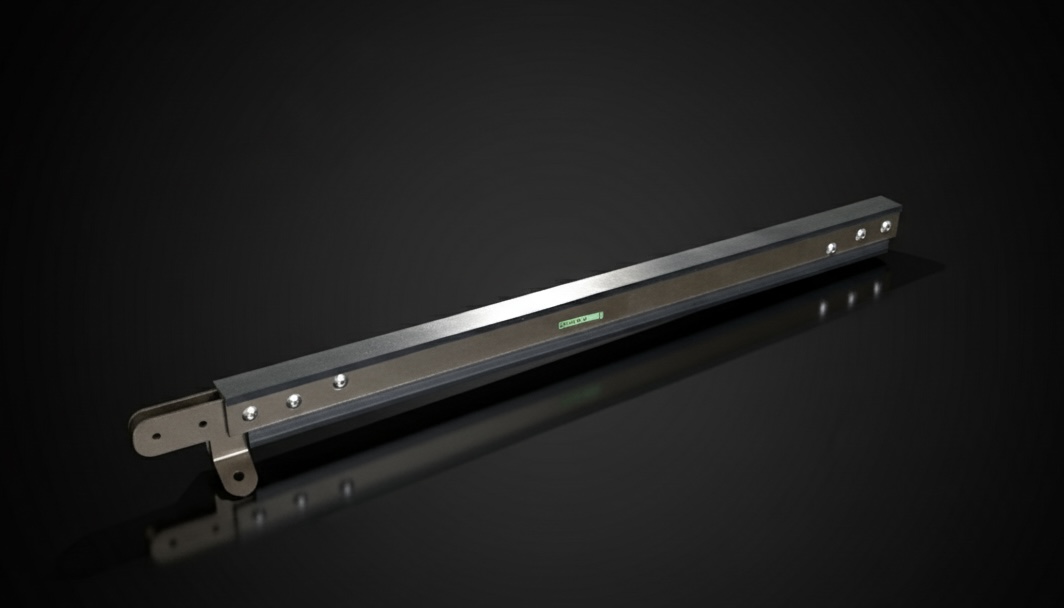

At VPI Innovative Solutions, we manufacture precision-engineered components used in robotic assemblies, motion systems, and automation modules. Our parts are designed to deliver dimensional accuracy, repeatability, and stability required for robotic actuation, control, and sensor integration.

We routinely produce components within ±5–6 micron tolerances, ensuring perfect fitment and alignment in complex assemblies.

Technical Capabilities

With multi-axis CNC machining, turn-mill, and sliding head technology, we manufacture intricate components requiring simultaneous operations and close-tolerance control.

Dimensional verification is carried out using Mitutoyo CMM systems and precision metrology equipment, ensuring compliance with design specifications.

Materials We Machine

Our machining capabilities cover a wide spectrum of engineering and alloy materials, including:

- Stainless Steels: SS304, SS316, SS416

- Aluminium Alloys: AL6061, AL7075, AL2024

- EN Series Steels: EN8, EN19, EN24

- Case-Hardening Steels: 16MnCr5, 20MnCr5, 16NiCr4, 18CrNiMo7-6, SCM420

- Brass, Copper, and Titanium

Post-Machining & Finishing

We provide complete post-machining and finishing support, including:

- Heat Treatments: Case hardening, carburizing, nitriding, quenching, tempering

- Surface Treatments: Nickel, Zinc, Anodizing, Electroless coatings

- Grinding, Lapping, and Super-finishing for low-friction movement and assembly reliability

All processes are executed to ensure dimensional stability, wear resistance, and consistent surface quality.

Our Focus

With deep precision engineering expertise and robust inspection systems, VPI Innovative Solutions supports the energy sector through components that meet tight tolerance requirements, demanding surface finish standards, and complex geometrical challenges — delivering performance where precision defines reliability.