Electronics Industry

Welcome to VPI Innovative Industries

Electronics Summary

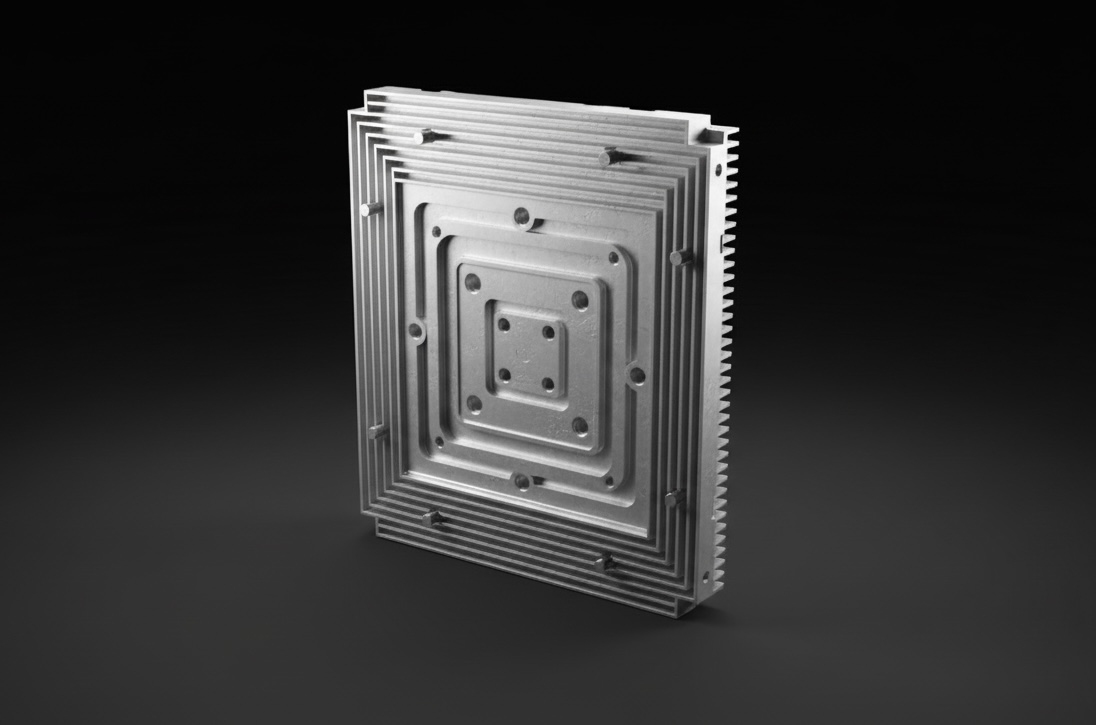

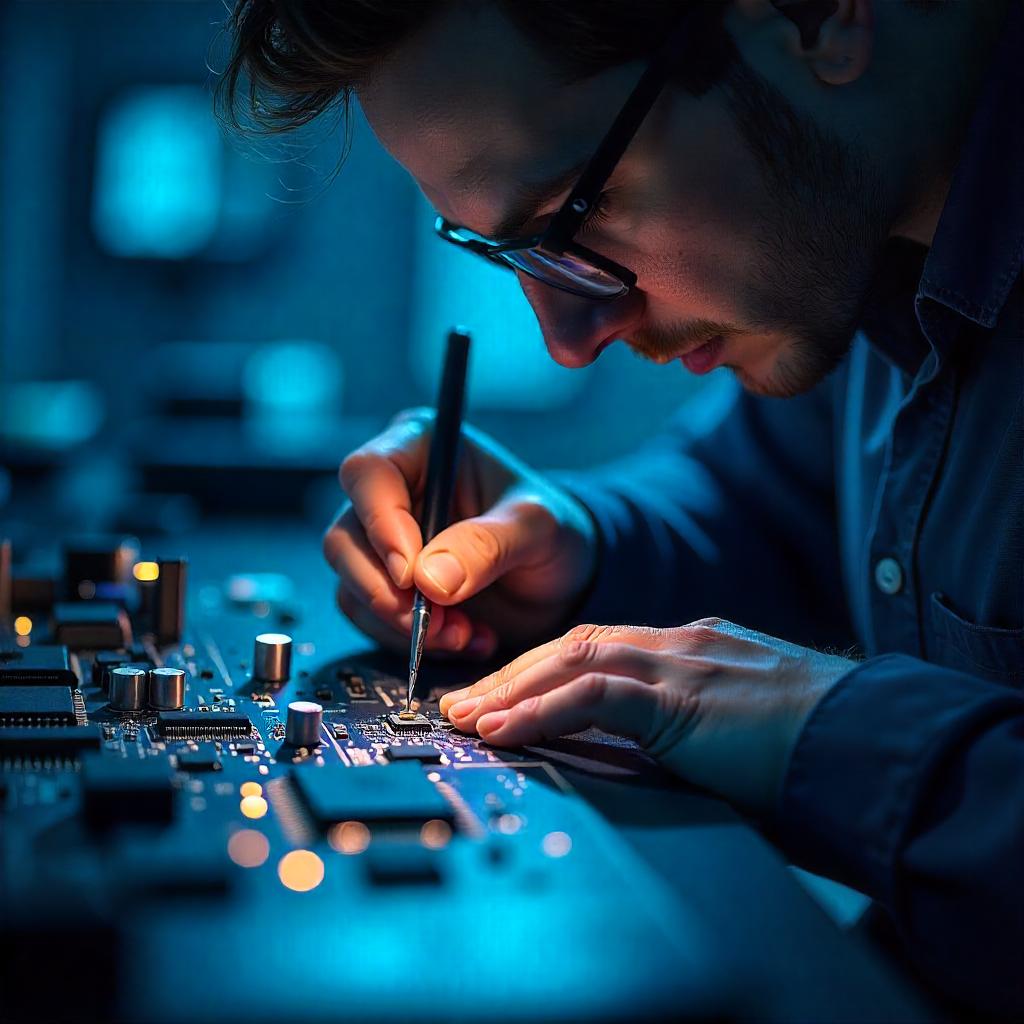

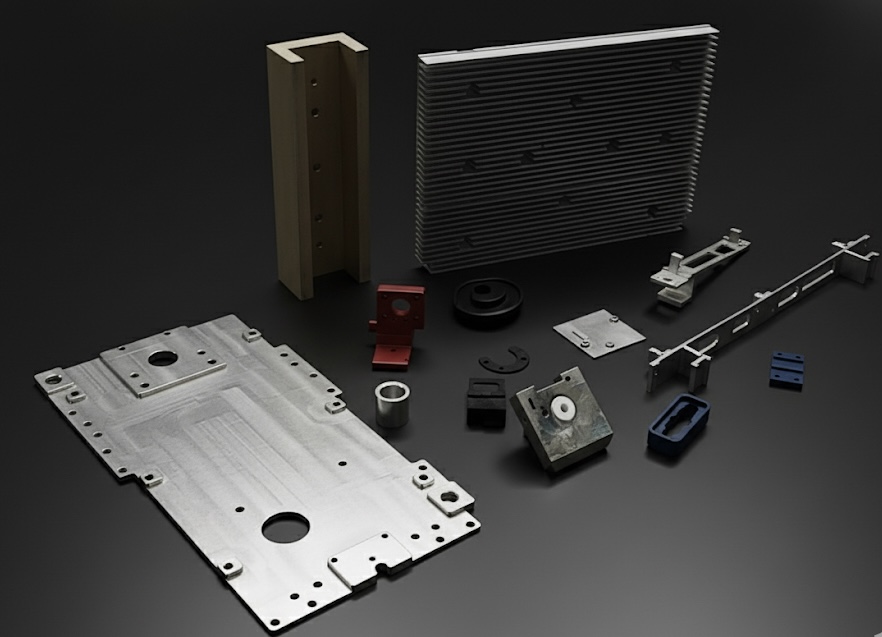

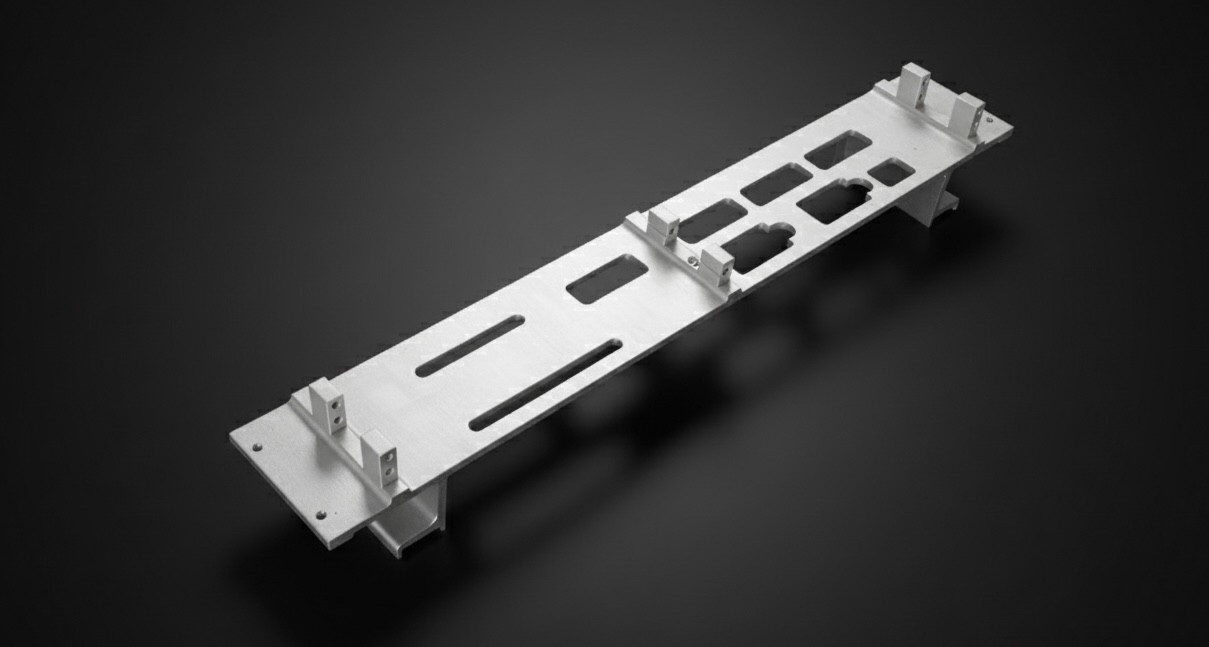

At VPI Innovative Solutions, we specialize in the manufacture of precision-machined components for the electronics and semiconductor industry, where compactness, accuracy, and surface quality are critical. Our machining systems are optimized for micro-scale components as small as 0.5 mm, ensuring precise dimensional control and consistent quality in every production batch.

Technical Capabilities

Equipped with multi-axis CNC machining, turn-mill centers, and sliding head technology, we produce micro and miniature precision parts with stable dimensional accuracy and burr-free edges.

Our inspection infrastructure, powered by Mitutoyo CMM, profile projectors, and surface roughness measurement systems, ensures full traceability and compliance with electronic component standards.

Materials We Machine

Our primary focus is on high-grade aluminium alloys for their superior machinability, conductivity, and stability. We also work with select non-ferrous and specialized materials suited for electronic assemblies, including:

- Aluminium Alloys: AL6061, AL7075, AL2024

- Brass and Copper Alloys for conductive applications

- Stainless Steels and Engineering Plastics for structural and insulating components

Post-Machining & Finishing

We provide specialized finishing operations to achieve optimal surface characteristics and aesthetic quality:

- Anodizing and Passivation for corrosion protection and electrical insulation

- Micro-deburring and Ultrasonic Cleaning for contamination-free surfaces

Polishing and Super-finishing for high reflectivity and smooth contact surfaces

Our Focus

With advanced process control and micro-machining capability, VPI Innovative Solutions supports the electronics sector with components that meet stringent dimensional standards, high surface finish requirements, and compact design challenges — ensuring reliability in every precision-built electronic assembly.