Advance Critical R&D

Welcome to VPI Innovative Industries

Energy Summary

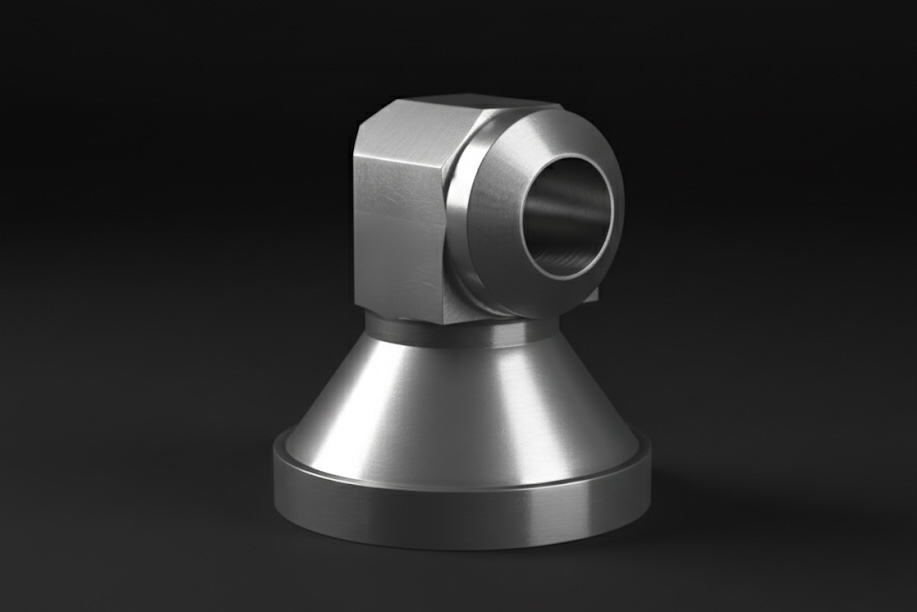

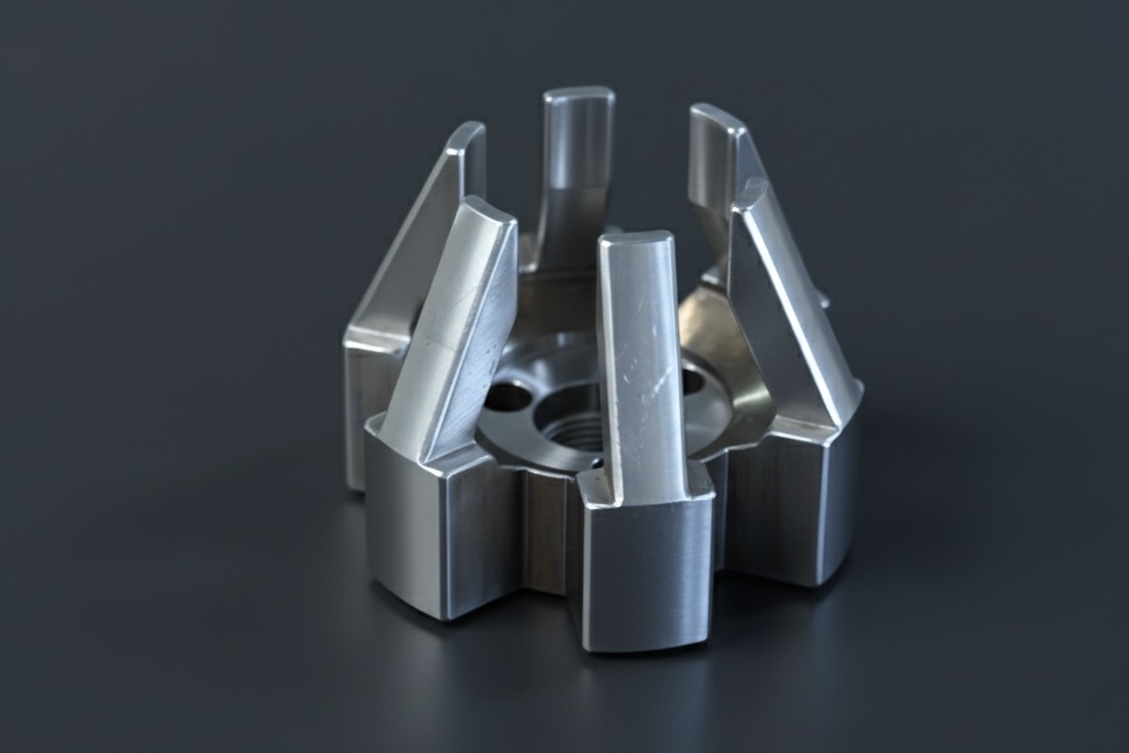

At VPI Innovative Solutions, we manufacture precision-engineered components for advanced and specialized applications that demand the highest levels of accuracy, stability, and material performance. These parts are often used in mission-critical, high-stress, and high-temperature environments, where even minor deviations can impact functionality.

Technical Capabilities

With a combination of multi-axis CNC machining, turn-mill centers, 5-axis Wire EDM, and micro-machining technology, we achieve fine surface finishes and dimensional accuracies within 10 microns on complex geometries.

Our process control systems ensure stability, traceability, and repeatability across all machining operations — from prototype validation to production-ready runs.

Materials We Machine

We specialize in high-performance and difficult-to-machine materials required for demanding environments, including:

- Titanium Alloys: Ti-6Al-4V and other aerospace/medical-grade variants

- Special Stainless Steels: SS316L, SS420, SS440C, 17-4PH, and Duplex grades

- Tool & Die Steels: H13, D2, SKD11

- Case-Hardening Steels: 16MnCr5, 20MnCr5, SCM420

- High-Strength Aluminium Alloys: AL7075, AL6082

- Copper, Brass, and Nickel-Based Alloys

Post-Machining & Validation

We offer end-to-end finishing and validation, including:

- Heat Treatment, Coating, Grinding, and Super-Finishing

- CMM-based dimensional inspection, surface profiling, and micro-geometry verification

- Process documentation and traceability for prototype and production components

Our 5-axis Wire EDM capability enables the production of burr-free, sharp-edged, and intricate contours, especially valuable in tooling, energy, and specialized instrumentation components.

Our Focus

Through advanced process engineering, material expertise, and precision validation systems, VPI Innovative Solutions supports R&D, prototype development, and mission-critical industries by delivering components that meet stringent functional, dimensional, and surface finish requirements — ensuring reliability in every one-of-one and specialized part we produce.